With the continuous development of technology, anti-counterfeit color-changing ink has become one of the indispensable important technologies in the modern printing industry. Anti-counterfeit color-changing ink can produce different colors on the product surface through specific processes and chemical combinations, thus protecting the brand and product quality. This article will focus on the working principle, application fields, production processes, detection methods, market status and development trends, and technological innovation directions of anti-counterfeit color-changing ink.

I. Working principle and application fields of anti-counterfeit color-changing ink

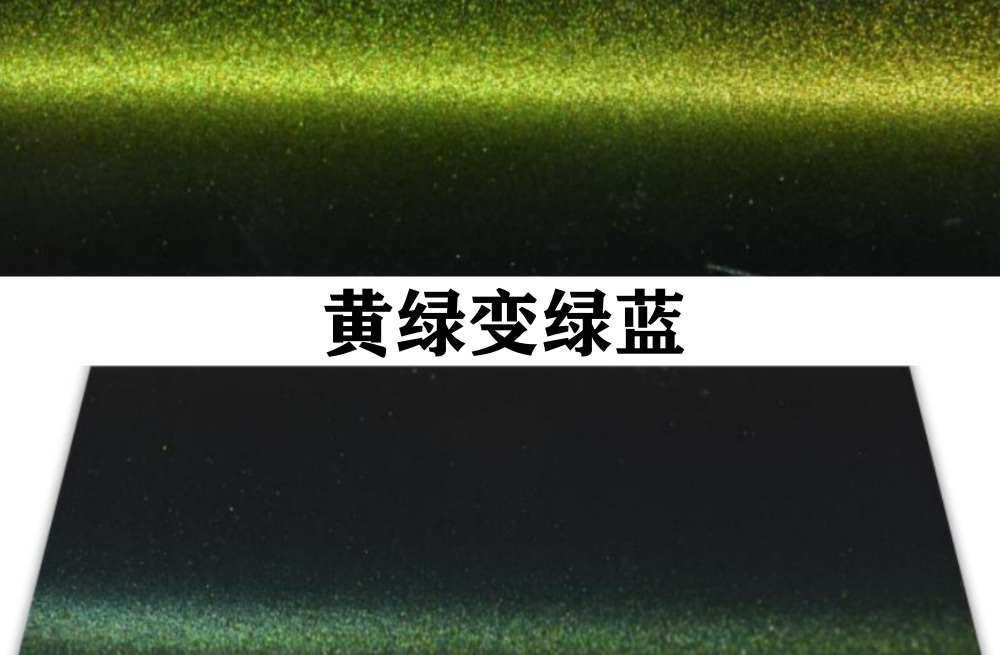

Anti-counterfeit color-changing ink mainly controls the chemical composition and photosensitizer addition amount to produce reversible or irreversible color changes in the ink under light or chemical reaction. Anti-counterfeit color-changing ink has a wide range of applications, including food, medicine, cosmetics, printing, and other industries, especially in high-end brands, high-value products, and important documents and certificates.

II. Production processes and detection methods of anti-counterfeit color-changing ink

The production process of anti-counterfeit color-changing ink generally includes raw material selection, formula design, solvent and pigment mixing, reaction time, precipitation separation, precipitation washing, centrifugal dehydration, and other links. At the same time, the detection method of anti-counterfeit color-changing ink is also very important, including color change observation, UV detection, microscope detection, infrared spectrum analysis, and other methods.

III. Market status and development trends of anti-counterfeit color-changing ink

With the continuous improvement of brand effects and intellectual property awareness, the demand for anti-counterfeit color-changing ink in the market has shown a growing trend. Especially as the country increases its crackdown on counterfeiting, the application of anti-counterfeit color-changing ink in commodity packaging and important certificates is constantly expanding. Currently, the main manufacturers in the anti-counterfeit color-changing ink market are domestic companies such as Jiadu Technology, Printing Medicine, Yiwei Lithium Energy, and international companies such as Japan's Toyo and the United States' Sun Chemical. In the future, with continuous technological innovation and cost reduction, the prospects of the anti-counterfeit color-changing ink market are promising.

IV. Technological innovation of anti-counterfeit color-changing ink

Technological innovation of anti-counterfeit color-changing ink is an important driving force for industry development. Currently, technological innovation of anti-counterfeit color-changing ink mainly focuses on the following areas:

Improvement and optimization of raw materials to improve ink stability and color brightness.

Improvement and innovation of photosensitizers to achieve faster and more precise color-changing effects.

Improvement and optimization of production processes to improve production efficiency and reduce costs.

Enhancement of anti-counterfeit effects, such as combining color-changing ink with micro-nano technology to achieve more complex color-changing effects and improve anti-counterfeit performance.

V. Conclusion

Anti-counterfeit color-changing ink is an important technology in the modern printing industry. Through its special color-changing effect, it can effectively protect brands and product quality and fight against counterfeiting. With continuous technological innovation and expanding application fields, the prospects of the anti-counterfeit color-changing ink market are promising. In the future, technological innovation and market demand will become important driving forces for industry development.

HiBlueStar

电话:15050450799(微信同号)

© HiBlueStar Sitemap