Optically variable pigments are a special type of pigment that possess unique optical properties compared to ordinary pigments. Here, a new method for manufacturing optically variable pigments is introduced. The optically variable pigments produced using this method have particles that are shaped like geometric shapes, numbers, letters, and other special shapes, which is a significant improvement in the level of anti-counterfeiting technology while still maintaining the basic optical properties of optically variable pigments.

Currently, the shaping of pigment particles is usually done using methods such as laser ablation, pressure crushing, specific templates, or substrate separation. For example, lasers can be used to engrave hollow patterns on large pieces of pigment. However, these methods are complicated and costly, and cannot be applied to mass production. Moreover, the shape of optically variable pigment particles is subject to many limitations, and the degree of customization is low.

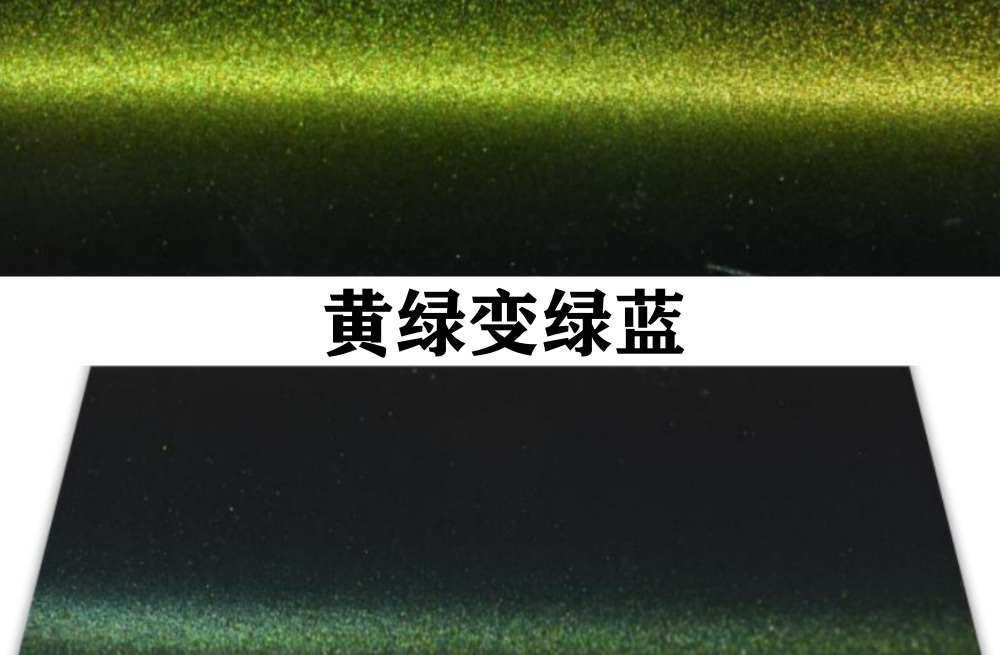

The new manufacturing method described here involves directly molding a shaping layer onto a substrate. This shaping layer is divided into three regions: a flat region, a first surface micro-embossed structure, and a second surface micro-embossed structure. Since the coating of the micro-embossed structure is thin and easy to damage, different coatings can be dissolved to obtain coatings of different thicknesses, thereby forming optically variable pigment particles with different optical effects.

HiBlueStar

电话:15050450799(微信同号)

© HiBlueStar Sitemap