Photochromic ink, commonly known as color-changing ink or color-shifting ink, for example: red-green, gold-silver, etc. It has strong photochromic properties and significant color differences, making it difficult to replicate and highly counterfeit-proof. Many countries around the world use this type of ink for currency or valuable securities. The manufacturing method of photochromic anti-counterfeiting ink is generally to dissolve photochromic color-changing pigments in solvents and make them into microcapsule pigments. Adhesives are added to the dissolved pigments according to different purposes. A better manufacturing method is to dissolve photochromic color-changing pigments into monomers, crush these polymer ultrafine particles into powder, and use them as pigments. Compared with microcapsule ink, the ink made by this method has a 10 times higher light resistance. These powders can be used as pigments in water-based ink, oil-based ink, plastic ink, and all adhesives.

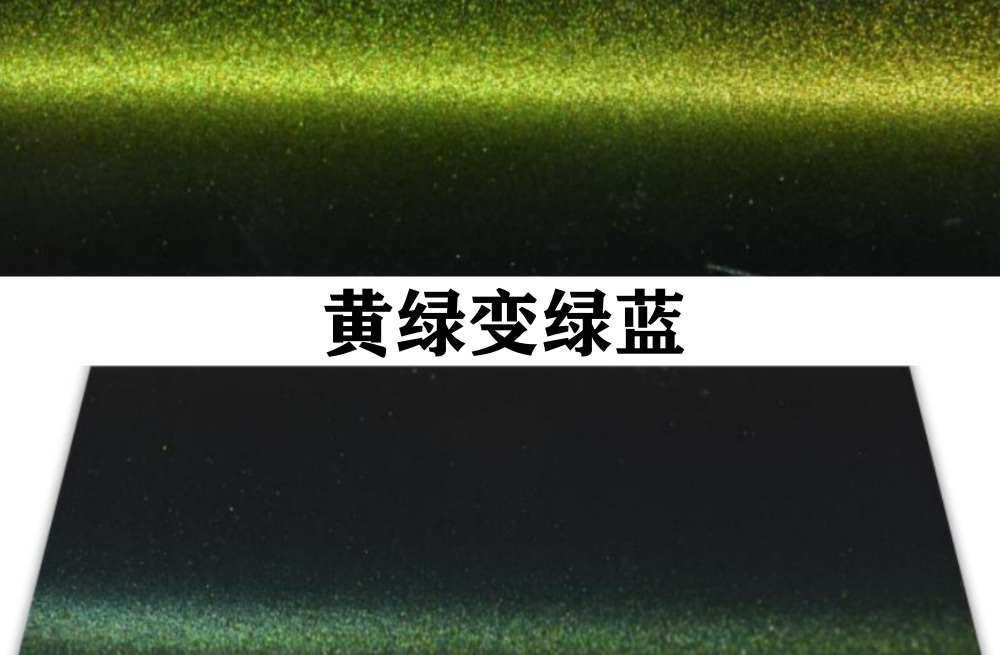

Interference-type photochromic ink used in banknote printing is the most complex new anti-counterfeiting ink. This ink has the characteristic of showing different colors at different angles under natural light. These dynamic color changes are also the best way to distinguish counterfeit currency that uses photochromic ink. Moreover, this type of anti-counterfeiting technology cannot be copied by photocopiers or scanners, and has high counterfeit resistance. The characteristics of this anti-counterfeiting technology are simple implementation, low cost, good concealment, bright colors, simple inspection, and strong reproducibility. It is the preferred anti-counterfeiting technology for currencies, certificates, and trademarks in various countries.

HiBlueStar

电话:15050450799(微信同号)

© HiBlueStar Sitemap